Unlocking Power: Your Guide to Exploring Jaw Crushers for Sale

Wiki Article

Efficiently Reuse Products With the Power of a Jaw Crusher

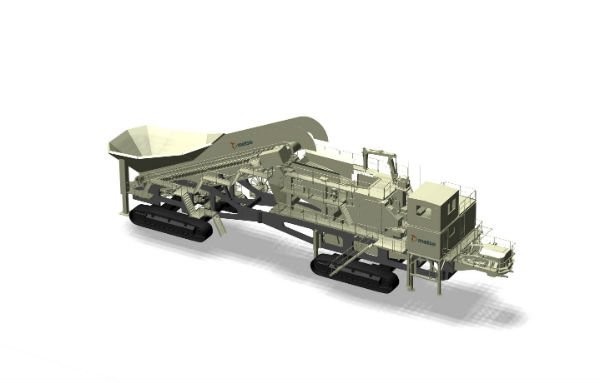

In today's globe, the relevance of reliable recycling can not be overemphasized. With the raising need for lasting methods, markets are regularly seeking ingenious services to reduce waste and make best use of source use. One such option is the use of a jaw crusher, a powerful device that has revolutionized the reusing procedure. This interesting piece of equipment supplies countless advantages, from its ability to crush a wide variety of products to its potential in enhancing reusing procedures. It is not simply regarding the power of the jaw crusher; there are several various other elements to consider to make certain an effective recycling operation. In this conversation, we will certainly look into the benefits of a jaw crusher, the products appropriate for crushing, the factors to consider for recycling procedures, and important upkeep and security tips. So, allow us explore just how a jaw crusher can play a critical duty in effectively recycling products (jaw crushers for sale).Advantages of a Jaw Crusher

The benefits of a jaw crusher are various and make it a crucial device for efficient recycling of materials. One of the main advantages of this machine is its ability to produce an uniform and consistent product dimension. The jaw crusher's layout enables large items of product to be squashed to a smaller sized dimension, leading to a much more workable and uniform product. This is specifically advantageous in recycling applications, where the goal is to generate regular product for reuse.

An additional benefit of a jaw crusher is its high capacity. jaw crushers for sale. These machines are made to manage big amounts of product, enabling for effective processing and raised performance. This is particularly essential in recycling operations, where huge amounts of material need to be refined swiftly

Materials Ideal for Squashing

Different materials are suitable for crushing in a jaw crusher, depending upon their physical homes and make-up. Jaw crushers are flexible machines that are commonly made use of in demolition, construction, and mining markets to crush products right into smaller sizes. Among the crucial consider establishing the viability of a material for squashing is its hardness. Tougher materials such as quartz, basalt, and granite are commonly crushed in jaw crushers as a result of their high compressive strength. These products can withstand the stress exerted by the jaws of the crusher, leading to efficient crushing.One more vital consideration is the abrasiveness of the material. Products such as sedimentary rock, dolomite, and sandstone are known to be rough and can create too much wear on the jaws of the crusher. With appropriate upkeep and the usage of wear-resistant products for the jaw plates, these products can still be efficiently crushed.

Furthermore, the dimension and form of the product additionally play a duty in determining its suitability for crushing. Jaw crushers are particularly effective in crushing large, hard, and irregularly shaped materials. They might not be as reliable in crushing smaller, softer, and much more uniform materials.

Recycling Operation Considerations

When taking into consideration recycling procedures, there are several key factors to think about. It is crucial to evaluate the type and amount of products that will be processed. This will certainly determine the size and ability demands of the jaw crusher that will be used in the reusing procedure. Furthermore, it is important to consider the desired final result size. Different crushers have various abilities in terms of lowering materials to a specific dimension variety. Therefore, recognizing the end product demands is vital in selecting the proper jaw crusher for the recycling procedure.Another crucial factor to consider is the operational expense of the reusing operation. This consists of the price of maintaining the jaw and obtaining crusher, along with the cost of power and other sources needed for its operation. It is essential to select a jaw crusher that supplies high efficiency and low operating expense to ensure the success of the reusing procedure.

Upkeep and Safety Tips

Thinking about the essential nature of maintenance and security in a reusing procedure, it is vital to apply effective approaches to make sure the smooth performance of the jaw crusher and protect the wellness of workers entailed. Normal upkeep is essential for the jaw crusher to operate at its peak performance. This consists of evaluating the equipment routinely, inspecting for any type of indications of my link damage, and resolving any kind of issues promptly. Lubrication is also necessary to stop rubbing and overheating, so it is very important to comply with the maker's guidelines for oiling and greasing the device. jaw crushers for sale.Furthermore, safety preventative measures must be purely adhered to in order to protect against mishaps and injuries. All employees operating the jaw crusher need to receive correct training on its use and safety and security procedures.

Normal evaluations and upkeep schedules need to be established to make certain that the jaw crusher is working ideally and safely. By following these upkeep and security suggestions, reusing operations can optimize the efficiency of their jaw crushers while prioritizing the wellness of their employees.

Optimizing Efficiency With a Jaw Crusher

To take full advantage of the performance of a jaw crusher, it is important to carry out reliable strategies and methods. Among the vital strategies is to guarantee appropriate feed control. This involves maintaining a controlled and constant feed price to the crusher, which aids to prevent overloading and take full advantage of throughput. Furthermore, the dimension and kind of feed product need to be carefully considered. It is essential to match the click for source jaw crusher's abilities to the particular demands of the material being processed. Adjusting the jaw crusher's closed side setting (CSS) can also play a significant role in taking full advantage of effectiveness. The CSS is the smallest distance in between the jaw plates throughout the squashing procedure. By changing the CSS, the size of the product can be controlled, causing far better fragment form and size distribution. Regular upkeep and examinations are critical for making sure ideal performance and maximum performance. This consists of checking and replacing used components, lubing the crusher frequently, and keeping the crusher tidy. In addition, checking the crusher's efficiency with regular measurements and information evaluation can assist determine opportunities for renovation and maximize the crusher's operation. By carrying out these techniques and strategies, drivers can make best use of the effectiveness of a jaw crusher and achieve much better general productivity in their reusing operations.Final Thought

In this discussion, we will dig right into the advantages of a jaw crusher, the materials appropriate for squashing, the factors to consider for reusing operations, and important upkeep and safety and security tips. Let us check out exactly how a jaw crusher can play a crucial role in effectively recycling products.

Checking the crusher's efficiency through regular official site measurements and data analysis can assist recognize opportunities for improvement and optimize the crusher's operation.In final thought, a jaw crusher uses many advantages in successfully reusing products. On the whole, the usage of a jaw crusher confirms to be a reliable solution for recycling materials.

Report this wiki page